预计未来几年智能制造市场将实现大幅增长。

这一增长的主要驱动力是对互联供应链和知识型制造的日益增长的需求,它们配备了复杂的控制、建模、传感和模拟功能。

先进的制造技术和数字化工厂将改变生产中心、工厂、企业和整个价值链,从而推动第四次工业革命。

智能制造的兴起

The positive effect of investments and government initiatives to stimulate the adoption of smart manufacturing has been one of the most powerful dynamics driving market growth. The fact that both emerging markets and developed countries are assertively following this path is expected to drive added growth. The principal growth opportunities for smart manufacturing solution providers are in the aerospace & defense and automotive industries.

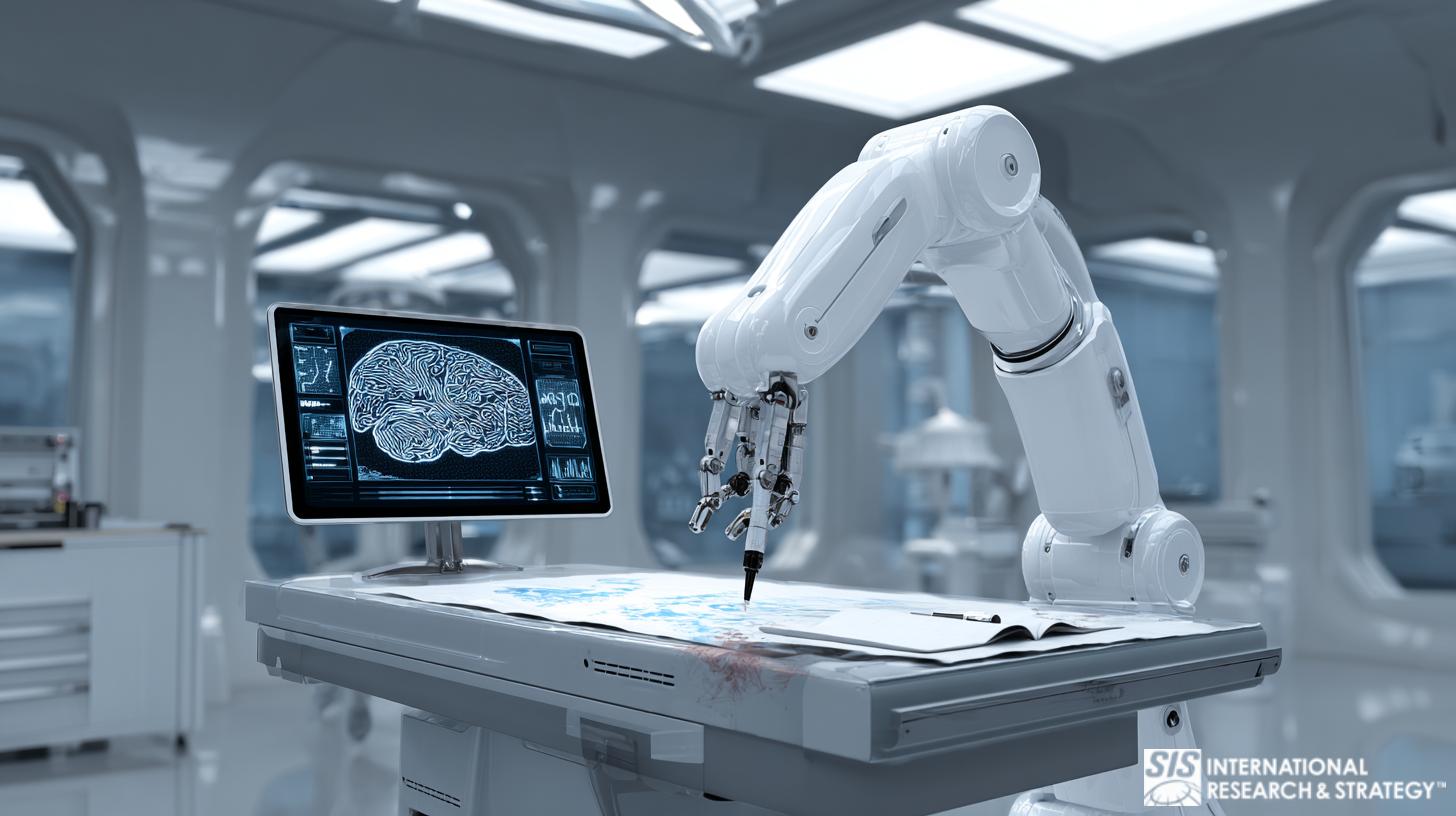

Other elements driving the rise of smart manufacturing include intensification in emphasis on regulatory compliance, the development of the Internet of Things, a rise in the use of industrial robots, and growth in demand for smart automation processes. The industrial robot is a disruptive technology, which is anticipated to radically transform manufacturing processes.

3D 打印的兴起也为企业带来了新机遇。从头到尾利用计算机辅助设计快速制造产品和原型的能力提高了效率,并改变了许多行业的格局。

智能制造的实际用途

Smart manufacturing is recognized as essential to the future of competitive manufacturing. This is partly due to their use of smart process applications, a new kind of software that combines the benefits of advanced analytics and process applications to help factories and other businesses to manage their processes, resources, and systems more efficiently.

In order to speak to a vibrant and international market, smart manufacturing takes advantage of cutting-edge manufacturing tools and information to get flexible and reconfigurable manufacturing practices. It allows all information flows and physical processes to be available when and where they are required across multiple industries, holistic manufacturing supply chains, large companies, and small and medium enterprises.

Smart manufacturing will reorganize production by facilitating programmable, flexible, and embedded forms of manufacturing. Technologies will enable new ways of doing business and participation, creating new products and services and offering new ways of systematizing production. A network centric approach to production in the coming decade will replace linear production processes with flexible and intelligent network approaches.

人类和设计在智能制造中的重要性

工人们越来越担心自动化,担心智能制造流程会取代他们的工作。然而,尽管人们对自动化的担忧持续存在,但人们对大规模接管仍持怀疑态度。虽然自动化对工业的未来可能至关重要,但人类永远不会被完全取代。

Human skills remain indispensable for numerous jobs, even as production systems veer increasingly towards informatics, sensors, robotics, mobile devices, and other forms of automation, making the marriage between machines and humans critical to success. It’s essential that companies fully understand how to best design and operationalize both technological and human factors, since human factors will play an essential role in the future of manufacturing, where technology and people are being integrated more closely and intensively than ever before.

智能制造为何有用?

智能制造有几个优点。它们使制造商能够更好地跟踪产品的历史、操作特性和使用模式。制造商还可以通过产品内置的云规则或算法远程控制产品。上述监控和跟踪,加上新的控制水平,可以实现产品优化。智能制造还使生产商能够达到一定程度的自主性。

The creation of the 物联网 means that everything is now connected: machines, products, warehouses, factories, and consumers. In addition to optimizing products, manufacturers can now optimize factories to improve and integrate production capacity, leading to more efficient maintenance, more reliable production lead times, and lower levels of stock.

智能制造催生了智能员工队伍,由敏锐、积极进取、反应灵敏的数字人才组成。随着智能技术承担起职责和一些繁琐的人工工作,各级决策者都需要利用物联网、高级分析、云技术和大数据的力量来处理复杂的数据驱动知识。